The EP-621 thermosetting epoxy powder has excellent leveling, smooth appearance and strong bonding force. It can provide reliable anti-corrosion protection and effectively reduce the friction coefficient of the inner wall of the pipeline and the transmission resistance. It is mainly applied to the anti-corrosive coating on the inner wall of steel pipelines such as gas and water conveyance.

This product has been certified to meet the requirements of CSA Z245.20.18,SY/T0442-2010 and CJ/T120-2016 standards.

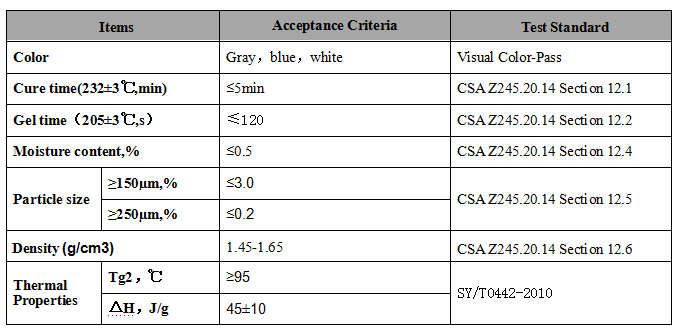

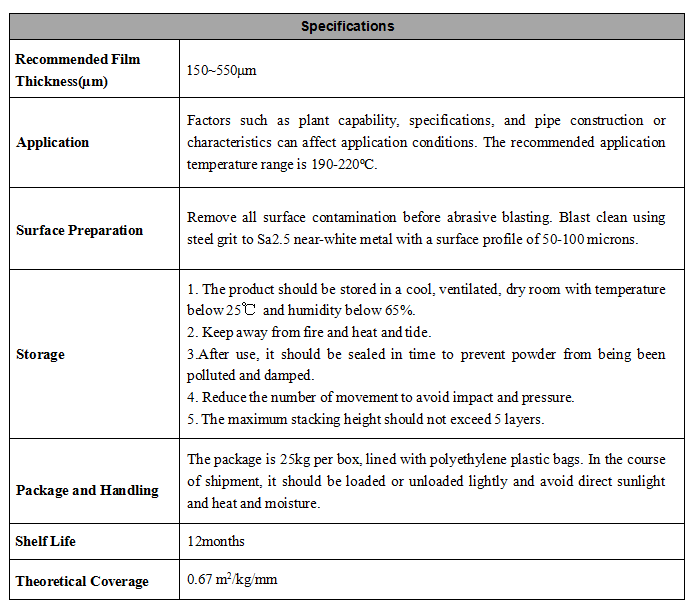

Powder Properties

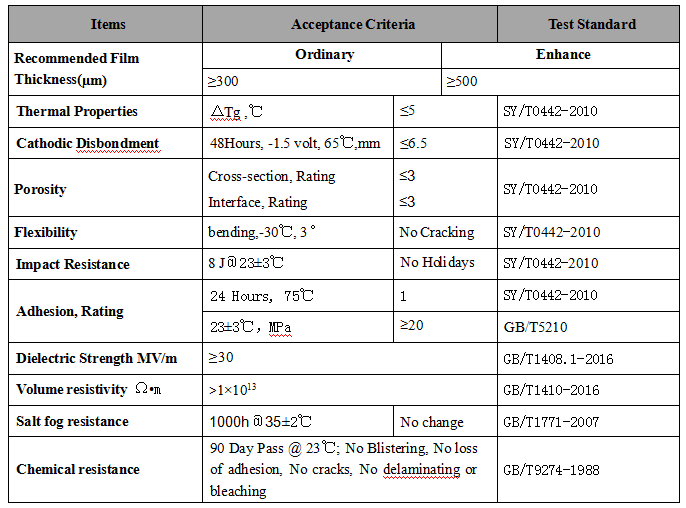

Film Properties

EP-621M Epoxy Powder Coating

The EP-621M thermosetting epoxy powder coating system is engineered to protect pipelines from corrosion in the most demanding operating environments. EP-621M is designed for anti-corrision in high temperature environment. It can be used in single layer, double layer or the prime layer of 3PP.

This product has been certified to meet the requirements of ISO21809-1 and CSA Z245.20-18 standards.

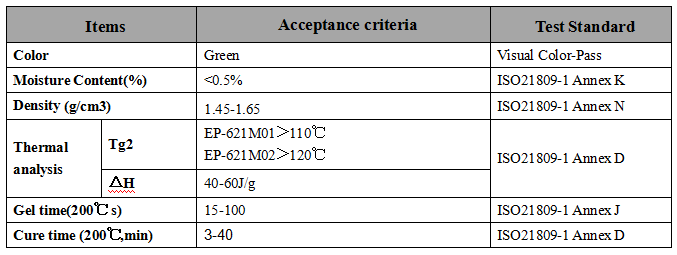

Powder Properties

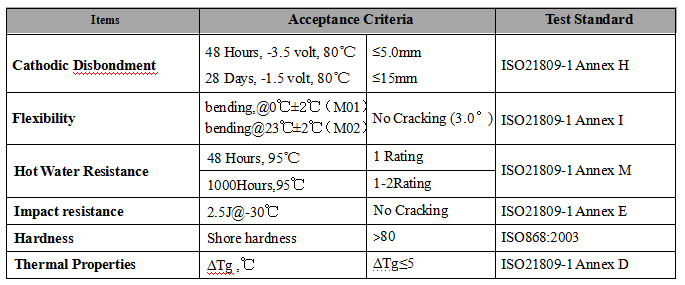

Film Properties

EP-621HH Epoxy Powder Coating

1Induction

EP-621HH is a kind of thermosetting epoxy powder coating, which is a special anti-corrosive powder coating designed for the corrosion of pipes used in high temperature environment. The product has excellent corrosion resistance and can be used for internal corrosion protection of oil drill pipe, oil pipe and casing.

This product meets the requirements of SY /T6717-2016 and SY / T0544-2016.

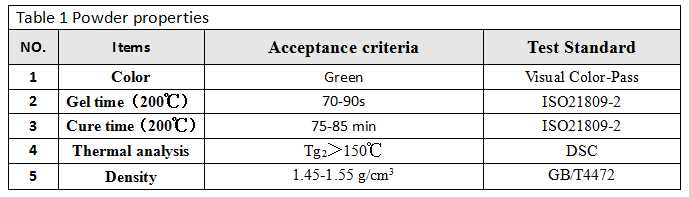

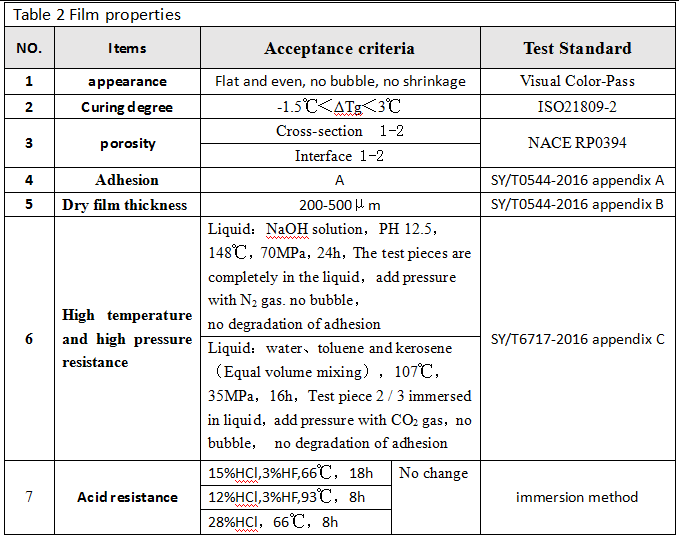

2 Performance

Note:

1 All data are based on laboratory testing and practical experience.

2 It is recommended that the product should pass process evaluation before mass use, so as to avoid unnecessary loss to customers due to various reasons such as process.

3 Application

1)Remove all surface contamination before abrasive blasting. Blast clean using steel grit to Sa2.5 near-white metal with a surface profile of 50-100 microns.

2)Clean the pipe surface thoroughly.

3)Special primer should be sprayed evenly with thickness less than 25 μ M. Note that the thickness of the primer should not exceed the depth of the anchor pattern.

4)Preheat: put the pipe sprayed with primer into the heating furnace for preheat,The recommended application temperature range is 170⁓190℃。

5)The powder coating is applied on the inner surface of the pipeline with a thickness of more than 200 μ M.

6)The coated pipe was put into the heating furnace and cured at 200 ± 10 ℃ for 80 ± 5 min to make the coating reach the best condition.

7)The properties of the coating were tested after natural cooling.

4 Storage

1)The product should be stored in a cool, ventilated, dry room with temperature below 25℃ and humidity below 65%.

2) Keep away from fire and heat and tide.

3) After use, it should be sealed in time to prevent powder from being been polluted and damped.

4) Reduce the number of movement to avoid impact and pressure.

5) The maximum stacking height should not exceed 5 layers.

5 Package and Handling

The package is 25kg per box, lined with polyethylene plastic bags. In the course of shipment, it should be loaded or unloaded lightly and avoid direct sunlight and heat and moisture.